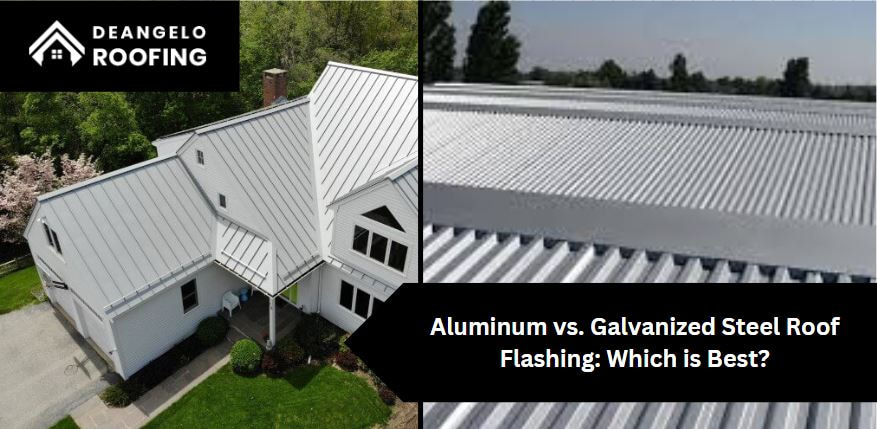

Aluminum vs. Galvanized Steel Roof Flashing: Which is Best?

Which roof flashing material is better—aluminum or galvanized steel? Choosing the right flashing can make a huge difference in protecting your home or commercial building from water damage. Both materials offer unique benefits, but they also have key differences in durability, cost, and maintenance.

This guide will break down the pros and cons of Aluminum vs. galvanized steel flashing, helping you make an informed decision based on your roof type, budget, and climate needs.

Importance of Roof Flashing:

Roof flashing plays a crucial role in protecting buildings from water damage. It acts as a barrier that directs water away from vulnerable areas like roof joints, edges, and valleys, preventing leaks and structural issues over time.

Purpose of Comparison: Aluminum vs. Galvanized Steel Flashing

When it comes to metal flashing, Aluminum vs. galvanized steel flashing are two popular choices—but which one is better for your roof?

This comparison aims to break down:

- Durability: Which material lasts longer in different conditions?

- Cost: Is aluminum worth the higher price, or is galvanized steel more cost-effective?

- Maintenance: Which material requires less upkeep?

- Weather Performance: Which metal handles moisture and temperature changes better?

By the end of this guide, you’ll have a clear understanding of which flashing material best suits your roof’s needs, ensuring better protection and long-term value.

Overview of Roof Flashing Materials

Aluminum Flashing:

- Lightweight & Corrosion-Resistant: Aluminum is easy to handle and naturally resistant to rust, making it ideal for moisture-prone areas.

- Malleable: Its flexibility makes it suitable for complex roof designs.

- Common Uses: Best for residential roofs, especially in coastal or humid regions.

Galvanized Steel Flashing:

- Strong & Impact-Resistant: Heavier and tougher than aluminum, offering greater strength.

- Zinc-Coated: The zinc coating provides rust protection but can wear off over time.

- Common Uses: Preferred for commercial buildings and areas needing extra durability.

Durability and Longevity

Aluminum:

- Corrosion Resistance: Naturally rust-resistant, making it perfect for damp climates.

- Lifespan: Typically lasts over 20 years with minimal maintenance.

Galvanized Steel:

- Corrosion Resistance: Protected by a zinc coating. If scratched or damaged, the underlying steel can rust.

- Lifespan: With proper care, it can last up to 40 years, depending on environmental factors.

Cost Analysis

Aluminum:

- Material Costs: Aluminum tends to be more expensive upfront compared to galvanized steel.

- Installation Costs: Since it is lightweight and easy to work with, labor costs can be lower.

Galvanized Steel:

- Material Costs: Galvanized steel is generally more budget-friendly initially.

- Installation Costs: Heavier and less flexible, which can increase labor expenses.

Maintenance Requirements

Aluminum:

- Upkeep: Minimal maintenance needed. Regular inspections for dents or physical damage help maintain its durability.

Galvanized Steel:

- Upkeep: Requires periodic checks to ensure the zinc coating remains intact, as damage can lead to rust formation.

Compatibility with Other Roofing Materials

Aluminum:

- Considerations: Should not be placed in direct contact with copper to avoid galvanic corrosion.

Galvanized Steel:

- Considerations: Avoid use with acidic materials or environments that can weaken the zinc coating.

Environmental Impact

Aluminum:

- Recyclability: Highly recyclable and considered an eco-friendly option due to minimal processing impact.

Galvanized Steel:

- Recyclability: Also recyclable, but the galvanization process involves more environmental impact due to chemical treatments.

Factors to Consider When Choosing Flashing

Selecting the right roof flashing material is essential for long-term durability and protection. Here are key factors to keep in mind:

1. Roof Design and Complexity

The shape and style of your roof play a big role in determining the best flashing material.

- Aluminum flashing is flexible and easier to shape, making it perfect for complex rooflines with multiple angles.

- Galvanized steel flashing, being more rigid, works better for simple roof structures where less bending is required.

2. Budget Considerations

Budget is often a deciding factor when choosing between aluminum and galvanized steel.

- Aluminum generally costs more upfront but can reduce labor expenses due to its easier handling.

- Galvanized steel is more affordable initially but may involve higher installation costs due to its heavier weight.

3. Climate and Environmental Factors

Your local climate can greatly affect the performance of roof flashing materials.

- Aluminum resists rust naturally, making it ideal for humid, coastal, or rainy regions.

- Galvanized steel performs well in dry climates but requires protection from moisture to avoid corrosion if the zinc coating is damaged.

4. Long-Term Maintenance Preferences

Think about how much maintenance you’re willing to commit to over the years.

- Aluminum requires minimal maintenance, just occasional inspections for dents or physical damage.

- Galvanized steel needs regular checks to ensure the zinc coating remains intact, as any damage could lead to rust.

Comparison Table: Aluminum vs. Galvanized Steel Flashing

| Feature | Aluminum Flashing | Galvanized Steel Flashing |

| Material Properties | Lightweight, flexible, corrosion-resistant | Heavy, rigid, coated with zinc for rust protection |

| Durability | Resists rust naturally, lasts 20+ years | Zinc coating prevents rust, lasts up to 40 years |

| Cost | Higher material cost, lower installation cost | Lower material cost, higher installation cost |

| Maintenance | Minimal maintenance, occasional dent checks | Requires regular inspection for coating integrity |

| Best Use Cases | Complex roof designs, coastal and humid areas | Simple roof structures, dry climates, high-impact zones |

| Weather Resistance | Excellent for moisture-prone areas | Good, but coating can wear off in extreme moisture |

| Environmental Impact | Highly recyclable, eco-friendly | Recyclable, but galvanization has higher environmental impact |

| Flexibility & Workability | Very flexible, easy to cut and bend | Rigid, harder to shape and cut |

| Structural Strength | Less strong, ideal for low-impact areas | Stronger, suitable for high-impact areas |

| Lifespan | 20-25 years with proper care | Up to 40 years with maintenance |

Conclusion:

So, which is the better choice:Aluminum vs. galvanized steel flashing ? It depends on your priorities. If you need lightweight, rust-resistant flashing with minimal upkeep, aluminum might be your best bet. On the other hand, galvanized steel offers rugged durability and a longer lifespan when properly maintained.

Understanding your roof’s design, local climate, and long-term maintenance preferences will help you choose the flashing material that offers the best protection for your property.

FAQs

Aluminum flashing is corrosion-resistant and lightweight, making it ideal for areas with mild weather. However, galvanized flashing is more durable in harsh conditions due to its steel base coated with zinc.

Galvanized steel is stronger and more durable, especially in harsh environments, while aluminum is lighter, more corrosion-resistant, and easier to work with for lighter-duty applications.

Aluminum flashing can corrode when it comes into contact with the alkaline materials in masonry, leading to premature wear and failure. Galvanized flashing is a better choice for masonry applications.

Aluminum drip edge is more corrosion-resistant and lightweight, making it ideal for areas with mild weather. Galvanized drip edge, on the other hand, is stronger and more durable in regions with harsher weather conditions.